An

HDPE manifold is a piping component used to distribute or collect fluids among multiple pipelines or system components. Manifolds are commonly used in various industries, including plumbing, HVAC (Heating, Ventilation, and Air Conditioning), industrial processes, irrigation, and more. HDPE manifolds offer the benefits of corrosion resistance, durability, and ease of installation that are characteristic of HDPE material.

Here are key points to understand about HDPE manifolds:

Function: HDPE manifolds serve as distribution points to direct fluid flow from one source to multiple destinations or to collect fluids from multiple sources into a single outlet. They help manage flow distribution and balance within a system.

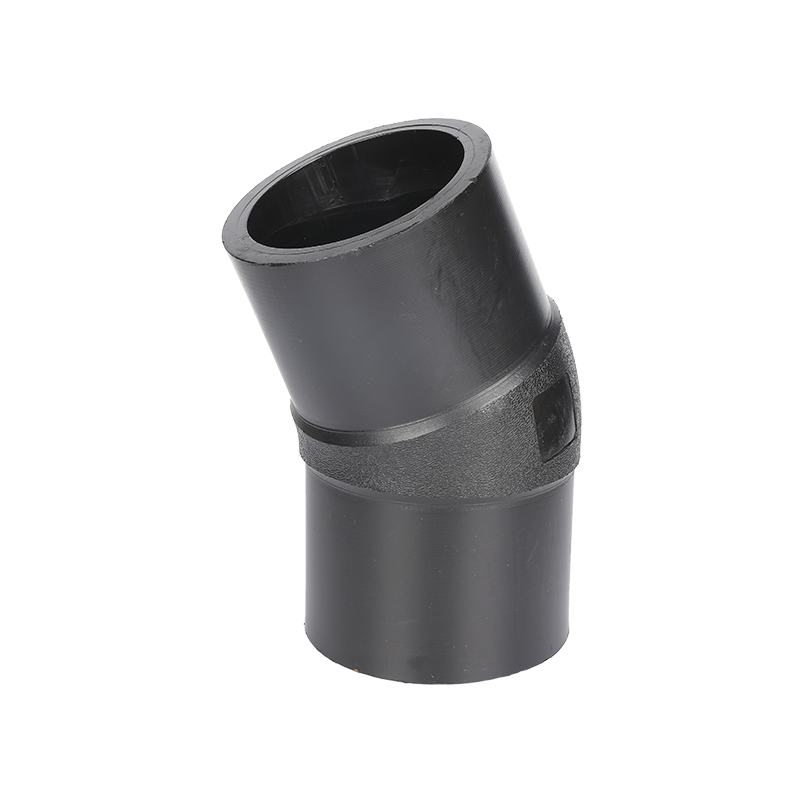

Construction: HDPE manifolds are typically constructed using HDPE pipes and fittings, including tees, reducers, elbows, and other components that allow for the branching and merging of pipelines.

Design and Configuration: Manifolds can be designed in various configurations, including linear, radial, and custom layouts, depending on the specific system requirements.

Applications: HDPE manifolds are used in a wide range of applications, such as water distribution systems, radiant heating systems, irrigation networks, chemical processing, and more

Advantages of HDPE: HDPE material is known for its corrosion resistance, durability, and flexibility. It is well-suited for applications where exposure to chemicals, moisture, and harsh environments is a concern.

Installation: HDPE manifolds can be installed using various methods, including butt fusion, electrofusion, or mechanical joining techniques. Proper installation is important to ensure leak-free connections and efficient fluid distribution.

Pressure and Temperature Ratings: Consider the pressure and temperature ratings of the HDPE manifold components to ensure they can handle the conditions of your application.

Compatibility: Ensure that the HDPE manifold components, such as pipes, fittings, and valves, are compatible with each other and with the fluid being transported.

HDPE manifolds play a crucial role in distributing fluids efficiently and effectively within a piping system. Whether you're designing a new system or retrofitting an existing one, choosing the right HDPE manifold configuration and components can help optimize flow distribution and ensure reliable performance.

English

English Español

Español русский

русский عربى

عربى

.jpg?imageView2/2/format/jp2)