HDPE 90 degree elbow butt fusion fitting produced ......

-

AddressZheJiang, China

-

Phone+86-17367068772

-

E-mail[email protected]

How does Hdpe Thread Fitting balance sealing and installation convenience in pipe connection?

HDPE Thread Fitting is widely used in water supply, drainage, gas, agricultural irrigation and other pipeline systems due to its excellent corrosion resistance, good flexibility and long service life. However, in the actual construction process, how to ensure the sealing of the connection while improving the installation efficiency is a key issue that engineers are concerned about.

1. Structural characteristics and advantages of HDPE threaded pipe fittings

HDPE threaded pipe fittings are usually injection molded with thermoplastic materials, with standard thread interfaces inside, which can be quickly connected with metal or plastic pipes. Its main features include:

Lightweight and durable: Compared with traditional metal pipe fittings, HDPE material is lighter, not easy to rust, and suitable for a variety of corrosive environments.

Standardized design: Follows international general thread standards (such as ISO 7/1, NPT, etc.), has strong compatibility, and is convenient for docking of different brands and systems.

Strong anti-vibration ability: Because HDPE has a certain elasticity, it can still maintain connection stability in foundation settlement or earthquake environment.

2. Key factors for achieving good sealing

Although threaded connections are widely used in traditional metal pipes, the following aspects should still be noted to achieve reliable sealing in HDPE pipe systems:

Thread accuracy and fit

The threads between the pipe fittings and the pipe must be accurately matched to avoid leakage due to excessive gaps. It is recommended to use special measuring tools to detect the thread size to ensure compliance with standard requirements.

Reasonable use of sealing materials

Applying sealant, wrapping raw tape (PTFE tape) or using O-rings on the threaded connection can effectively enhance the sealing performance. Especially in high-pressure or gas transmission application scenarios, the choice of sealing materials is crucial.

Anti-loosening design

Some HDPE threaded pipe fittings are equipped with anti-loosening buckles or locking nuts to prevent loose connections due to vibration or pressure changes, thereby affecting the sealing effect.

3. Practical methods to improve installation convenience

One of the major advantages of HDPE threaded pipe fittings is that they are easy to install, especially suitable for situations where on-site construction conditions are limited. Here are some ways to improve installation efficiency:

No need for hot melt or welding, lowering the technical threshold

Compared with traditional hot melt connection methods, threaded connection does not require professional equipment or high temperature operation. Ordinary workers can complete the installation after simple training, which greatly saves construction time and labor costs.

Modular design reduces on-site processing

HDPE threaded pipe fittings are mostly prefabricated products, which can be purchased and transported to the construction site in advance according to project requirements, reducing cutting, grinding and other processes, and improving the overall construction progress.

Applicable to complex terrain and maintenance scenarios

In underground pipe networks, renovation of old communities or temporary water supply systems, threaded connections are easy to disassemble and replace, especially suitable for later maintenance and local repairs.

4. Applicable scenarios and precautions

HDPE threaded pipe fittings are suitable for the following typical application scenarios:

Hot and cold water supply systems for homes and commercial buildings

Farm irrigation and sprinkler systems

Urban rainwater discharge and sewage treatment

Gas transmission (special gas-grade HDPE materials must be selected)

Note during use:

Avoid excessive tightening to cause deformation of pipe fittings or damage to threads;

Control the working temperature range to avoid long-term exposure to extreme high temperature environments;

For large-diameter or high-pressure systems, it is recommended to combine flanges or other auxiliary connection methods to enhance safety.

HDPE threaded pipe fittings are becoming an indispensable part of modern pipeline systems with their good sealing performance and convenient installation methods. Through precise thread design, reasonable sealing measures and scientific construction management, the long-term stable operation of the system can be guaranteed, and the engineering efficiency can be significantly improved. In the future, with the continuous advancement of material technology and connection technology, HDPE threaded pipe fittings will demonstrate their comprehensive advantages of high efficiency, environmental protection and economy in more fields.

Product Display

-

HDPE 90 degree elbow butt fusion fitting

-

HDPE 45 degree elbow butt fusion fitting

HDPE 45 degree elbow butt fusion fitting produced ......

-

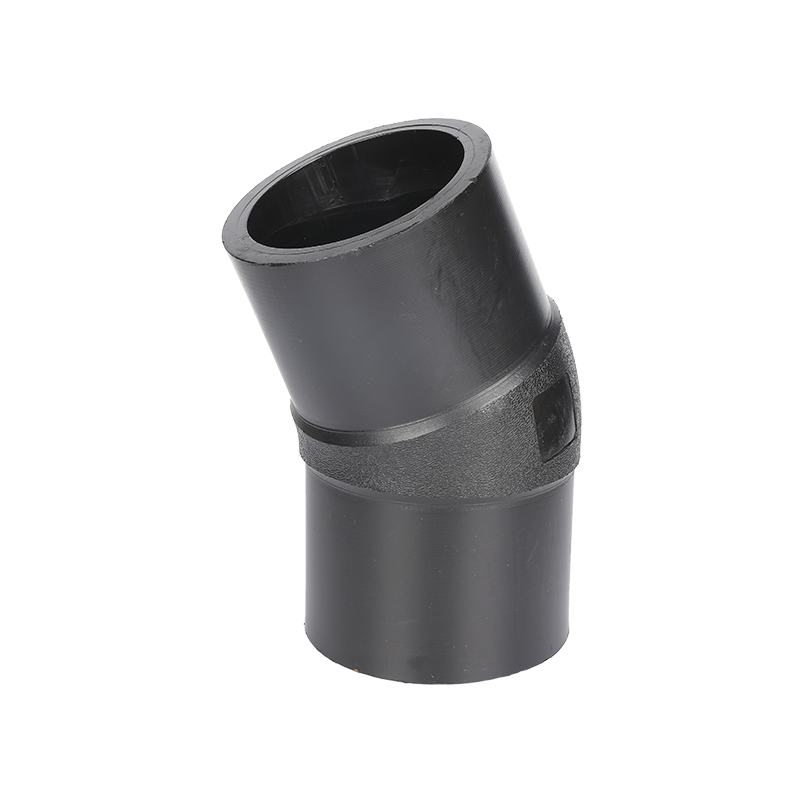

HDPE 22.5 degree elbow butt fusion fitting

HDPE 22.5 degree elbow butt fusion fitting produce......

-

HDPE equal tee butt fusion fittings

HDPE equal tee butt fusion fittings produced by in......

-

HDPE reducing tee butt fusion fitting

HDPE reducing tee butt fusion fittings produced by......

-

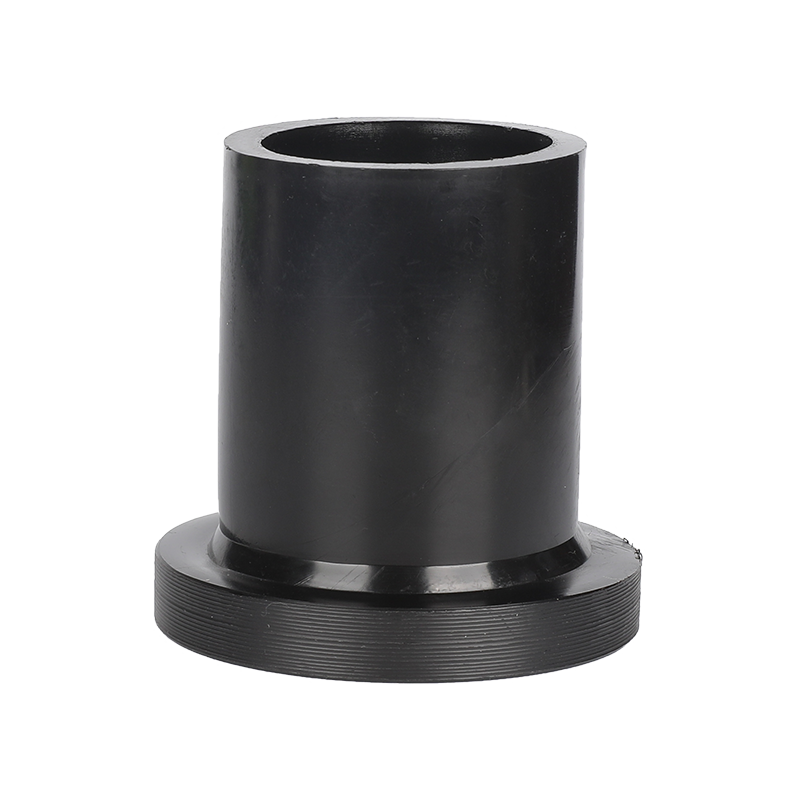

HDPE flange adaptor butt fusion fittings

HDPE flange adaptor butt fusion fittings produced ......

-

HDPE reducer butt fusion fitting

HDPE reducer butt fusion fitting produced by injec......

-

HDPE cross butt fusion fittings

HDPE cross butt fusion fittings produced by inject......

-

HDPE end cap butt fusion fitting

Mould injection hdpe end cap butt fusion fittings ......

-

PE/PPR socket fuison welding machine

PE/PPR socket fusion welding machine brief&fea......

-

Double U HDPE ground source pump fitting

Double U HDPE Ground source pump fitting produced ......

-

PIPE clamp HDPE ground source pump fitting

PIPE CLAMP HDPE Ground source pump fitting produce......

-

.jpg?imageView2/2/format/jp2)

Single U HDPE ground source pump fitting

single U HDPE Ground source pump fitting produced ......

-

U socket HDPE Ground source pump fitting

U socket HDPE Ground source pump fitting produced ......

English

English Español

Español русский

русский عربى

عربى

Contact Us