HDPE 90 degree elbow butt fusion fitting produced ......

-

AddressZheJiang, China

-

Phone+86-17367068772

-

E-mail[email protected]

Is Hdpe Valve suitable for high temperature or corrosive media?

HDPE valves have been widely used in municipal water supply and drainage, agricultural irrigation, chemical transportation and other fields due to their excellent corrosion resistance and good processing performance. However, whether it is suitable for high temperature or corrosive media needs to be comprehensively judged from multiple aspects such as material characteristics, usage environment, and industry standards.

Firstly, HDPE valves have excellent performance in corrosive media. HDPE is a chemically stable polymer material that hardly reacts with most acid, alkali, and salt solutions, and can remain stable even in liquids containing chloride ions, sulfides, or other corrosive components. This makes HDPE valves particularly suitable for use in highly corrosive conditions such as sewage treatment plants, seawater desalination systems, chemical pipelines, and industrial waste discharge. Compared with metal valves, HDPE valves do not rust or undergo electrochemical corrosion, and their sealing performance or structural strength will not be reduced due to long-term exposure to corrosive media. Therefore, HDPE valves are an ideal choice for transporting corrosive media in normal or low temperature environments.

However, regarding high-temperature media, HDPE valves have obvious limitations. The thermal deformation temperature of HDPE material is relatively low, and it is recommended that its continuous use temperature not exceed 60 ℃. The maximum temperature it can withstand in a short period of time is about 80 ℃. When the temperature exceeds this range, the material will gradually soften, causing a significant decrease in the mechanical strength of the valve, and even problems such as deformation and leakage. In addition, high temperature can accelerate the aging process of materials and shorten the service life of valves. Therefore, HDPE valves are not suitable for use in hot water systems, steam pipelines, or any applications that require operation at higher temperatures. In these applications, valves made of high-temperature resistant materials such as PP (polypropylene), PVDF (polyvinylidene fluoride), or stainless steel are more suitable.

It is worth noting that even within the allowable working temperature range, the pressure bearing capacity of HDPE valves will decrease with increasing temperature. For example, an HDPE valve with a rated pressure of PN16 at 20 ℃ may have its actual usable pressure reduced to PN10 or lower when the medium temperature rises to 50 ℃. Therefore, when designing the system, it is necessary to select the valve pressure rating based on the actual working temperature to ensure the safe and reliable operation of the system.

In addition, although HDPE material itself has certain UV resistance, long-term exposure to direct sunlight may still cause material aging. Therefore, it is usually recommended to take shading measures or choose products with added UV stabilizers for HDPE valves installed outdoors to extend their service life.

HDPE valves are very suitable for transporting corrosive media at room temperature, such as sewage, seawater, acid-base solutions, etc., exhibiting good corrosion resistance and economy. However, in application scenarios involving high-temperature media, HDPE valves are not suitable due to the thermal stability limitations of the material itself. When selecting valve materials, users should conduct a comprehensive evaluation based on the specific type of medium, temperature, pressure, and installation environment to ensure reasonable selection and system safety.

Product Display

-

HDPE 90 degree elbow butt fusion fitting

-

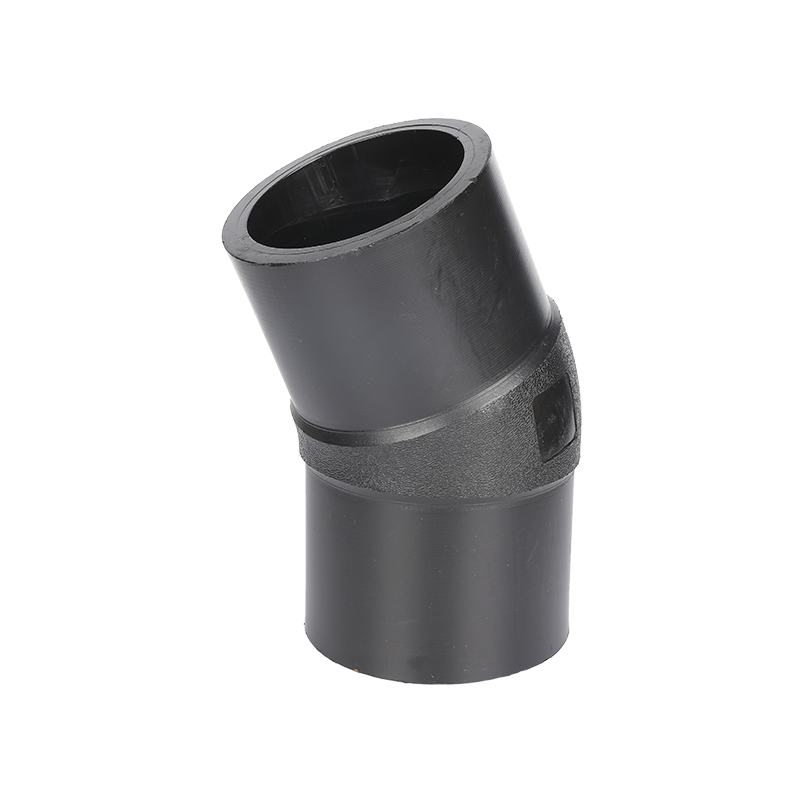

HDPE 45 degree elbow butt fusion fitting

HDPE 45 degree elbow butt fusion fitting produced ......

-

HDPE 22.5 degree elbow butt fusion fitting

HDPE 22.5 degree elbow butt fusion fitting produce......

-

HDPE equal tee butt fusion fittings

HDPE equal tee butt fusion fittings produced by in......

-

HDPE reducing tee butt fusion fitting

HDPE reducing tee butt fusion fittings produced by......

-

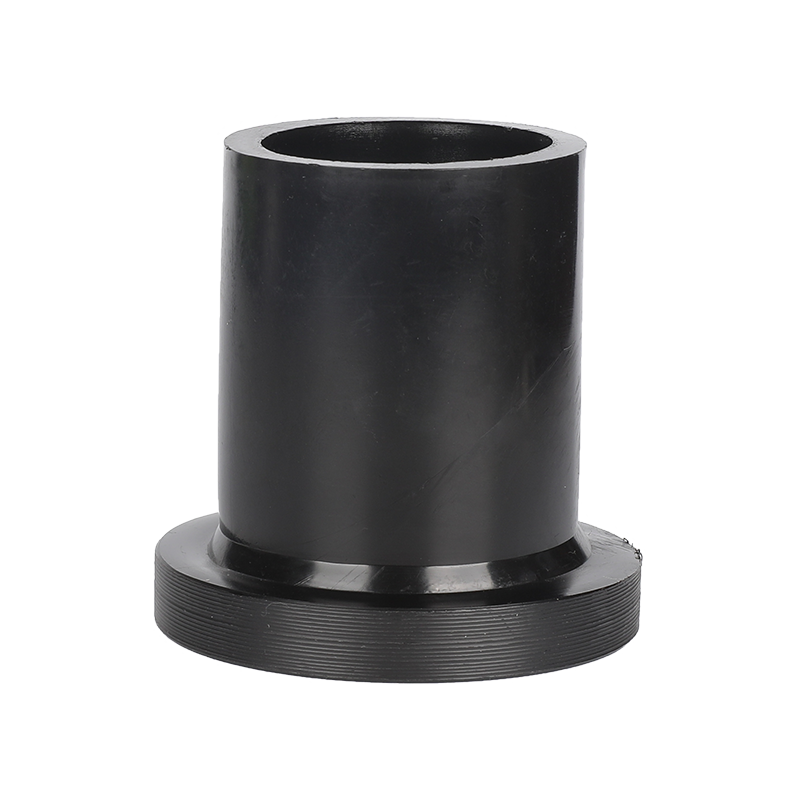

HDPE flange adaptor butt fusion fittings

HDPE flange adaptor butt fusion fittings produced ......

-

HDPE reducer butt fusion fitting

HDPE reducer butt fusion fitting produced by injec......

-

HDPE cross butt fusion fittings

HDPE cross butt fusion fittings produced by inject......

-

HDPE end cap butt fusion fitting

Mould injection hdpe end cap butt fusion fittings ......

-

PE/PPR socket fuison welding machine

PE/PPR socket fusion welding machine brief&fea......

-

Double U HDPE ground source pump fitting

Double U HDPE Ground source pump fitting produced ......

-

PIPE clamp HDPE ground source pump fitting

PIPE CLAMP HDPE Ground source pump fitting produce......

-

.jpg?imageView2/2/format/jp2)

Single U HDPE ground source pump fitting

single U HDPE Ground source pump fitting produced ......

-

U socket HDPE Ground source pump fitting

U socket HDPE Ground source pump fitting produced ......

English

English Español

Español русский

русский عربى

عربى

Contact Us