HDPE 90 degree elbow butt fusion fitting produced ......

-

AddressZheJiang, China

-

Phone+86-17367068772

-

E-mail[email protected]

Socket Fusion HDPE Fitting is a pipe solution for efficient connection

In modern construction projects, municipal water supply and drainage systems, and industrial fluid transportation, high-density polyethylene (HDPE) pipes have gradually become an ideal substitute for traditional metal and concrete pipes due to their excellent corrosion resistance, flexibility, and long life. In the installation process of HDPE pipe systems, Socket Fusion HDPE Fitting plays a vital role as a key connection method.

Socket Fusion uses molecular-level welding, and the strength of the connection part even exceeds that of the parent material itself. It has good tensile and compressive properties, ensuring the long-term stable operation of the pipeline system.

Convenient construction and high efficiency

Compared with traditional butt welding (Butt Fusion), Socket Fusion does not require complex processing and precise alignment of the pipe ends, and is simple to operate. It is suitable for environments with small spaces or limited site conditions.

Strong adaptability and wide application range

This technology is suitable for HDPE pipe systems of different pressure levels and different uses, especially for projects with frequent changes, many branches, and dense interfaces at the construction site.

High degree of automation and controllable quality

Modern electric fusion welding machines are equipped with intelligent control systems that can automatically identify pipe parameters and execute welding procedures, reducing human errors and improving the consistency and reliability of construction quality.

Due to its excellent anti-leakage performance, it is particularly suitable for drinking water and natural gas transmission systems with extremely high safety requirements.

In high-rise buildings, it is used for hot and cold water supply, rainwater drainage and other systems to improve the service life of the overall pipeline system.

In water-saving irrigation projects, HDPE pipes can be laid quickly with electric fusion pipe fittings and ensure long-term leakage-free operation.

Due to its good thermal stability and sealing, it performs well in underground buried environments.

Although Socket Fusion has many advantages, the following points should still be noted in actual applications:

Strictly follow the operating procedures: including pipe cleaning, insertion depth control, welding parameter setting, etc., to avoid connection failure due to improper operation.

Select qualified products: HDPE pipes and electric fusion pipe fittings that meet national standards (such as GB/T 13663, ISO 4427, etc.) should be selected to ensure material compatibility and welding quality.

Do a good job in post-testing: The connection effect can be verified by visual inspection, pressure testing, etc. to ensure the safe operation of the system.

With the advancement of smart city construction, HDPE pipe systems are moving towards intelligence. In the future, Socket Fusion HDPE Fitting is expected to integrate IoT sensors to achieve remote monitoring of pipeline connection status and fault warning. In addition, the research and development of environmentally friendly materials will also promote more sustainable HDPE pipe systems to the market.

As one of the core technologies in modern pipeline engineering, Socket Fusion HDPE Fitting is constantly expanding its application boundaries with its high efficiency, reliability and environmental protection. Whether in urban infrastructure construction or in green buildings and energy-saving systems, it has shown strong vitality. In the future, with the continuous advancement of technology, this connection method will continue to lead the development trend of the plastic pipe industry and provide safer and more efficient solutions for global infrastructure construction.

Product Display

-

HDPE 90 degree elbow butt fusion fitting

-

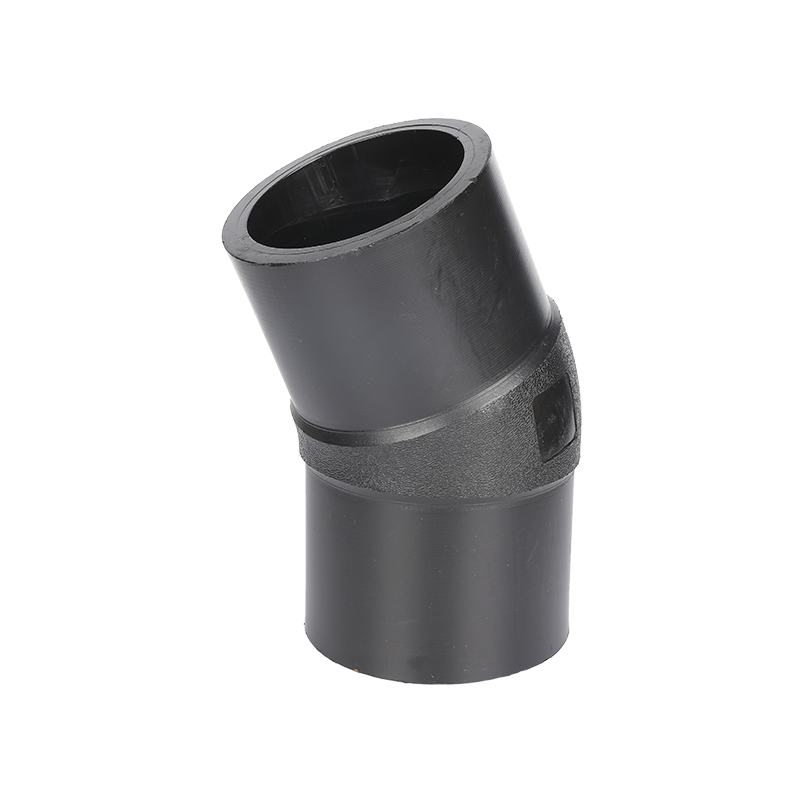

HDPE 45 degree elbow butt fusion fitting

HDPE 45 degree elbow butt fusion fitting produced ......

-

HDPE 22.5 degree elbow butt fusion fitting

HDPE 22.5 degree elbow butt fusion fitting produce......

-

HDPE equal tee butt fusion fittings

HDPE equal tee butt fusion fittings produced by in......

-

HDPE reducing tee butt fusion fitting

HDPE reducing tee butt fusion fittings produced by......

-

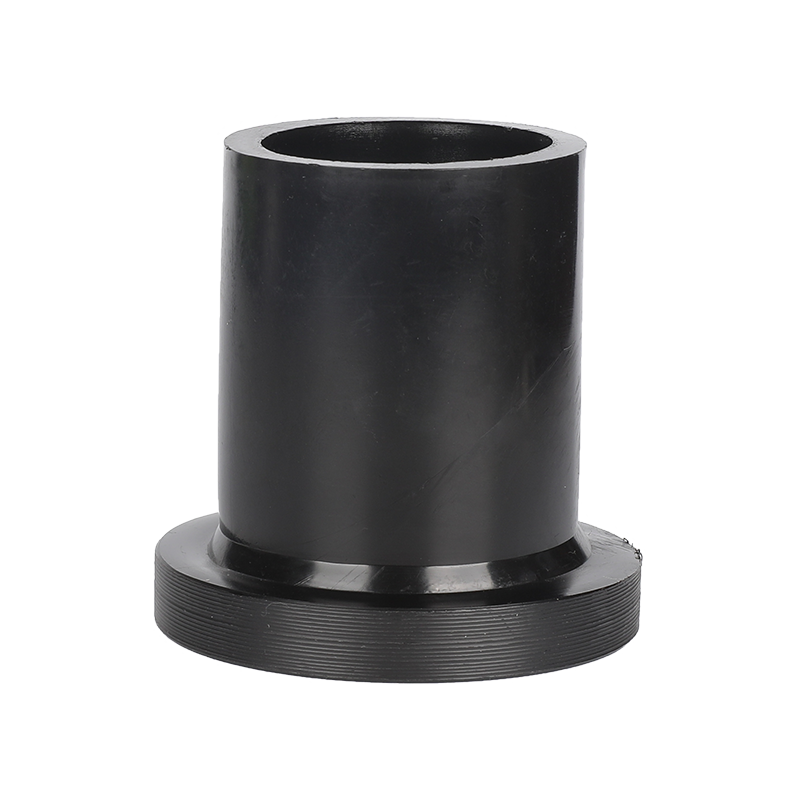

HDPE flange adaptor butt fusion fittings

HDPE flange adaptor butt fusion fittings produced ......

-

HDPE reducer butt fusion fitting

HDPE reducer butt fusion fitting produced by injec......

-

HDPE cross butt fusion fittings

HDPE cross butt fusion fittings produced by inject......

-

HDPE end cap butt fusion fitting

Mould injection hdpe end cap butt fusion fittings ......

-

PE/PPR socket fuison welding machine

PE/PPR socket fusion welding machine brief&fea......

-

Double U HDPE ground source pump fitting

Double U HDPE Ground source pump fitting produced ......

-

PIPE clamp HDPE ground source pump fitting

PIPE CLAMP HDPE Ground source pump fitting produce......

-

.jpg?imageView2/2/format/jp2)

Single U HDPE ground source pump fitting

single U HDPE Ground source pump fitting produced ......

-

U socket HDPE Ground source pump fitting

U socket HDPE Ground source pump fitting produced ......

English

English Español

Español русский

русский عربى

عربى

Contact Us