We also provide ASTM/ANSI HDPE 45 degree elbow butt fusion fitting available 1*1/2”-18” in SDR9,SDR11 & SDR17.Out diameter with inch size can also followed ASTM and ANSI standard which is different with ISO standard.

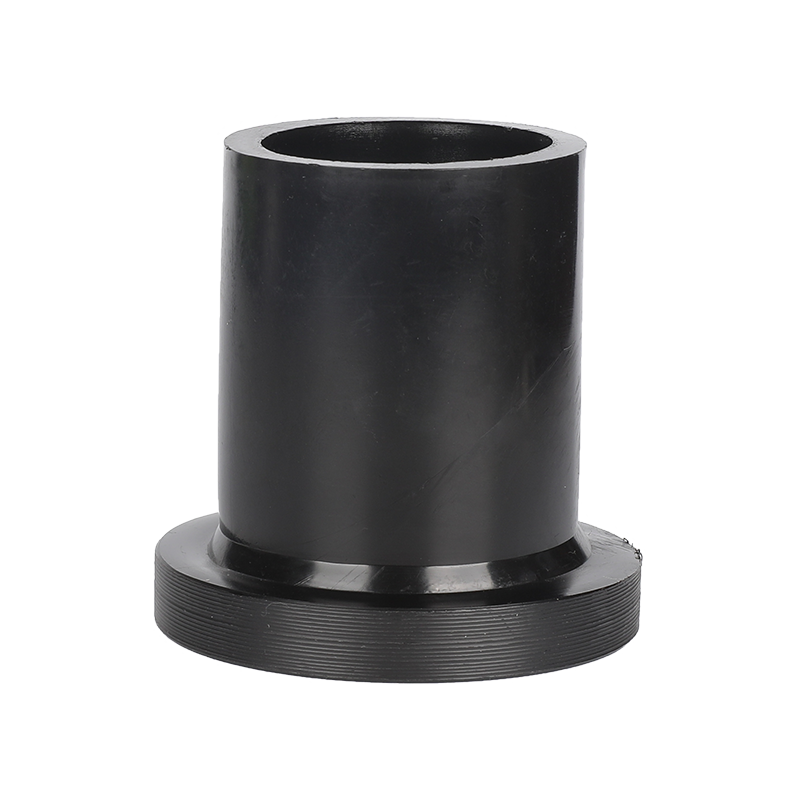

| Name | EN12201/ISO 4427 HDPE 45 degree elbow butt fusion fittings | ASTM /ANSI HDPE 45 degree elbow butt fusion fittings |

| Size | 63-800MM | 1*1/2”-18” |

| Pressure | SDR11 (PN16) ,SDR17 (PN10) | SDR9(PN20),SDR11(PN16),SDR17(PN10) |

| Material | PE100 | |

| Package | PP BAG | |

| Color | BLACK or based on required color | |

| Technics | Mould injection | |

| Loading port | Ningbo or Shanghai port | |

| Place of origin | Hangzhou |

| DN | L | H | SDR17 | SDR13.6 | SDR11 |

| 63MM | 160 | 63 | √ | √ | |

| 75MM | 185 | 70 | √ | √ | |

| 90MM | 228 | 79 | √ | √ | |

| 110MM | 265 | 90 | √ | √ | |

| 125MM | 250 | 87 | √ | √ | |

| 140MM | 270 | 92 | √ | √ | |

| 160MM | 305 | 100 | √ | √ | |

| 180MM | 340 | 105 | √ | √ | |

| 200MM | 355 | 112 | √ | √ | |

| 225MM | 398 | 120 | √ | √ | |

| 250MM | 420 | 129 | √ | √ | |

| 280MM | 485 | 139 | √ | √ | |

| 315MM | 510 | 150 | √ | √ | |

| 355MM | 550 | 164 | √ | √ | |

| 400MM | 600 | 179 | √ | √ | |

| 450MM | 560 | 130 | √ | √ | |

| 500MM | 610 | 135 | √ | √ | |

| 560MM | 650 | 135 | √ | √ | |

| 630MM | 710 | 145 | √ | √ | |

| 710MM | 835 | 180 | √ | ||

| 800MM | 900 | 180 | √ |

|

DN |

D (MM) |

L (MM)

|

L1 (MM) |

H (MM) SDR9 |

H (MM) SDR11 |

H (MM) SDR17 |

|

1*1/2" |

48.3 |

95 |

67 |

5.5 |

4.5 |

|

|

2" |

60.3 |

113 |

72 |

7 |

5.6 |

|

|

3" |

88.9 |

125 |

80 |

10 |

8.2 |

|

|

4" |

114.3 |

137 |

84 |

13 |

10.5 |

|

|

6” |

168.3 |

174 |

108 |

19 |

15.5 |

|

|

8” |

219.1 |

225 |

152 |

25 |

20.5 |

|

|

10” |

273 |

219 |

136 |

|

25.5 |

16.5 |

|

12” |

323.9 |

244 |

145 |

|

30 |

19.5 |

|

14” |

355.6 |

246 |

147 |

|

33 |

21.5 |

|

16” |

406.4 |

253 |

130 |

|

38 |

24.5 |

|

18” |

457.2 |

264 |

130 |

|

43 |

27.5 |

English

English Español

Español русский

русский عربى

عربى

.jpg?imageView2/2/format/jp2)