| SIZE | VOLTAGE | POWER | WORING TEMPERATURE | DEMENSION | WEIGHT |

| 20-63MM | 220v | 800W | 200-270℃ | 395*200*90MM | 5.0KG |

| 75-110MM | 220v | 1200W | 200-270℃ | 460*265*90MM | 5.0KG |

-

AddressZheJiang, China

-

Phone+86-17367068772

-

E-mail[email protected]

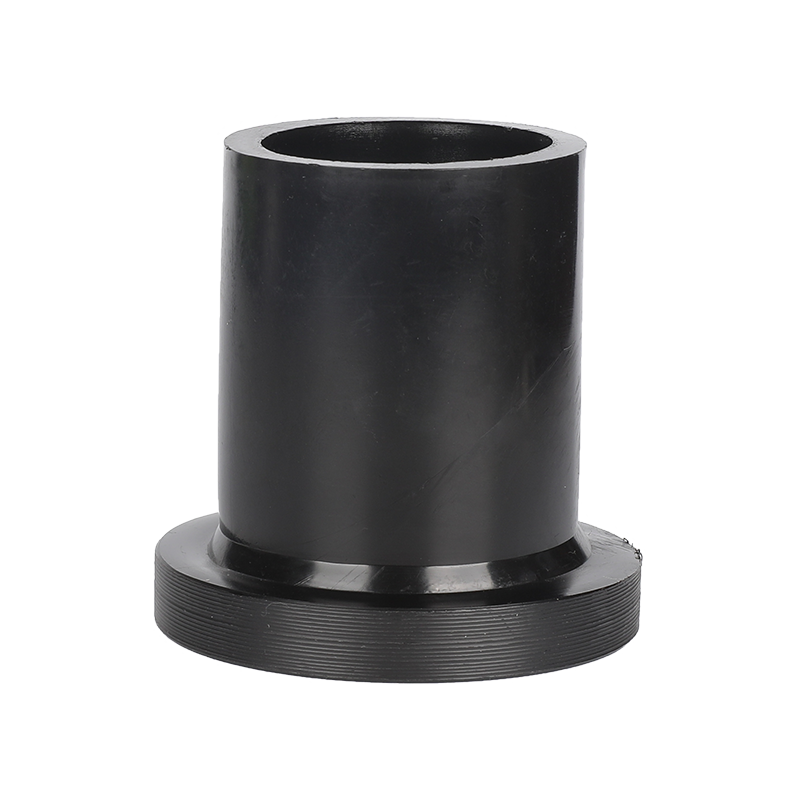

PE/PPR socket fuison welding machine

PE/PPR socket fusion welding machine brief&features

Get A Quote

❆ Sockets coated PTFE

❆ Individual temperature control of heating plate, which has a temperature display and adjustment function.

❆ Simple structure, mini dimension and easy operation.

About Us

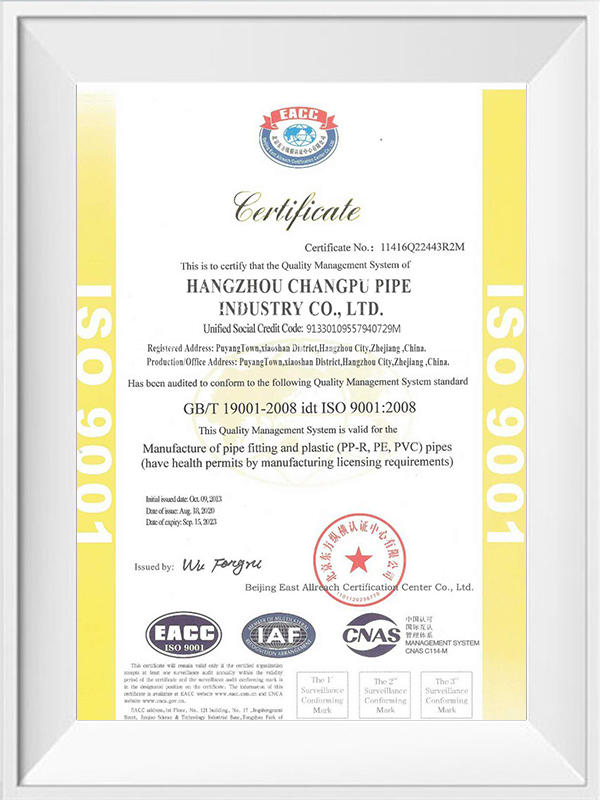

Hangzhou Changpu Pipe Industry Co., Ltd.

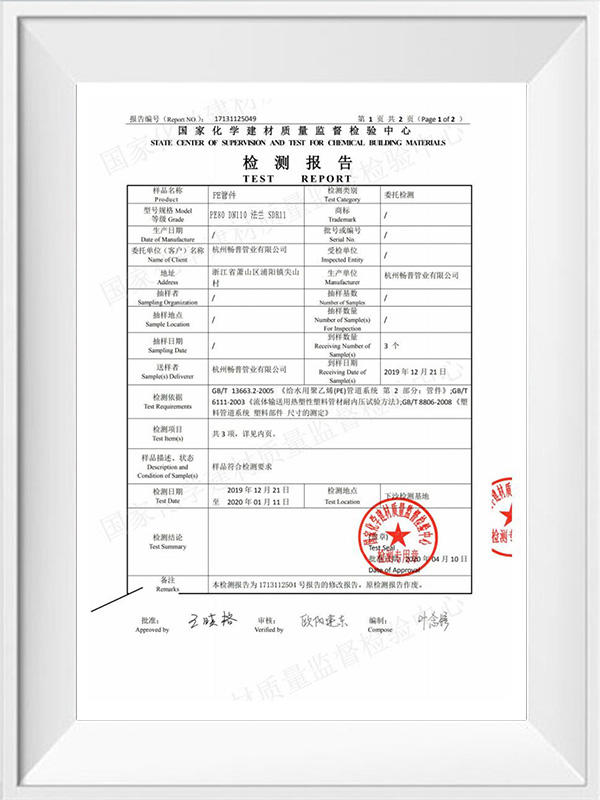

Hangzhou Changpu Pipe Industry Co., Ltd. was established in 2010, which is a professional factory major in the production of polyethylene (PE) Butt fusion fittings, Socket fusion fittings, Electrofusion fittings, PE stop valves, PE /Steel transition fittings, repair clamp ETC. PE/PPR socket fuison welding machine manufacturers and factory in China. Our products pass the test from National Chemical Building Materials Testing Center,all performance indicators are in compliance with the GB 15558.2 / EN1555 standards. Also they certified by ECM and obtain CE certification.

We focus on developing high-quality products for top-end markets. Our oem custom PE/PPR socket fuison welding machine are in line with international standards, and are mainly exported to Europe, America, Japan and other destinations around the world.We welcome domestic and foreign customers visit our company for guidance, exchanges and cooperation.

News

-

How does Hdpe Thread Fitting balance sealing and installation convenience in pipe connection?

HDPE Thread Fitting is widely used in water supply, drainage......--15 May 2025

READ MORE -

Socket Fusion HDPE Fitting is a pipe solution for efficient connection

In modern construction projects, municipal water supply and ......--09 May 2025

READ MORE -

Is Hdpe Valve suitable for high temperature or corrosive media?

HDPE valves have been widely used in municipal water supply ......--04 May 2025

READ MORE -

How to ensure the long-term reliability and durability of Butt Fusion HDPE Fittings in high pressure and high temperature environments?

Ensuring the long-term reliability and durability of Butt Fu......--23 Apr 2025

READ MORE -

Do Butt Fusion HDPE Fittings require additional protection to extend their service life?

Butt Fusion HDPE Fittings generally have a long service life......--14 Apr 2025

READ MORE

Product Knowledge

Safety features in a PE/PPR socket fusion welding machine are crucial to ensure the safety of operators and the proper execution of the socket fusion process. Different machines may offer varying safety mechanisms, but here are some common safety features that you should look for in a PE/PPR socket fusion welding machine:

Emergency Stop Button: A prominent emergency stop button allows operators to quickly halt the operation of the machine in case of any unexpected issues or emergencies.

Overheat Protection: Thermal sensors or controls monitor the temperature of the heating element and the fusion process. If the temperature exceeds safe limits, the machine automatically shuts down to prevent overheating and potential hazards.

Temperature Control and Display: Accurate temperature control ensures that the socket fusion is performed at the right temperature. Some machines feature digital temperature displays and controls that allow operators to set and monitor the temperature during the process.

Pressure Monitoring: Machines with pressure sensors can monitor and display the pressure applied during the socket fusion process. This helps ensure that proper pressure is maintained for a secure and reliable joint.

Safety Interlocks: These mechanisms prevent the machine from starting unless all clamps, fixtures, and safety guards are securely in place. This minimizes the risk of accidents due to improperly secured components.

Cooling Timer: After the fusion is complete, a cooling timer ensures that the fused joint cools down sufficiently before it's handled. This prevents accidental burns or damage to the joint.

Safety Guards: Machines may include protective guards that prevent operators from coming into direct contact with the heated elements during the fusion process.

Indicator Lights: Indicator lights signal various stages of the fusion process, helping operators follow the sequence correctly and indicating when it's safe to proceed.

User Manual and Safety Guidelines: A comprehensive user manual should provide clear instructions on safe machine operation, proper fusion techniques, and potential hazards to watch out for.

Training Recommendations: Some manufacturers may recommend or offer training programs to ensure that operators are knowledgeable about the machine's safe use and best practices.

Certifications and Compliance: Look for machines that are compliant with relevant safety standards and certifications, ensuring that they have undergone rigorous testing for safe operation.

Grounding and Electrical Safety: Machines should have proper grounding and electrical safety mechanisms to prevent electrical hazards during operation.

When choosing a PE/PPR socket fusion welding machine, thoroughly review the machine's safety features to ensure that they meet your requirements and promote a safe working environment. It's important for operators to receive proper training on the machine's operation, safety features, and emergency procedures to minimize risks during the socket fusion process.

English

English Español

Español русский

русский عربى

عربى

.jpg?imageView2/2/format/jp2)