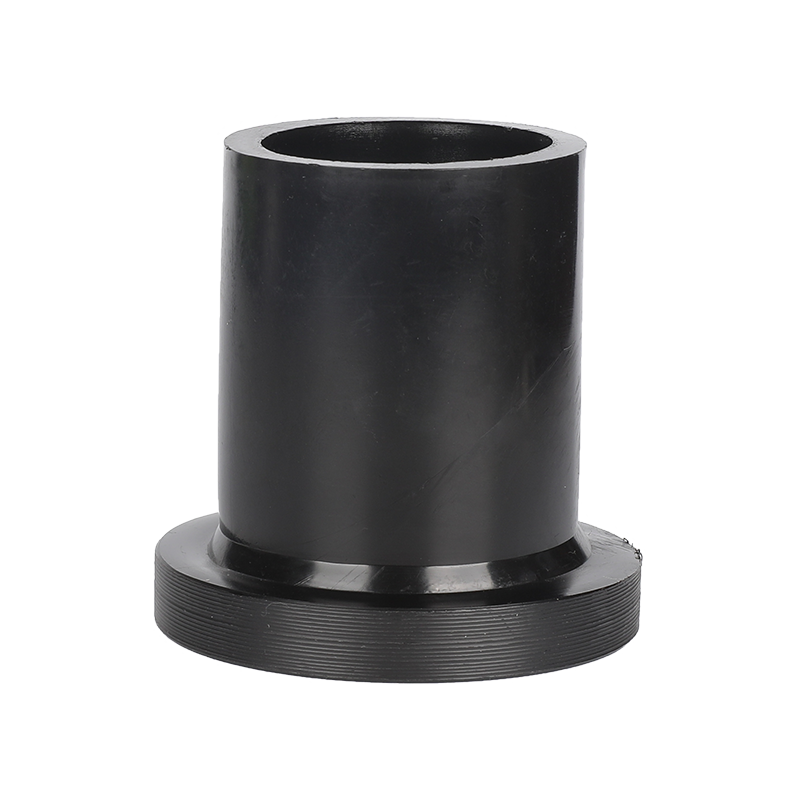

To determine whether the pressure rating of an

HDPE equal tee butt fusion fitting is suitable for your intended application and operating conditions, you need to consider the following factors:

Operating Pressure:Identify the maximum and typical operating pressures of your piping system.

Pressure Fluctuations:Consider if your application involves pressure fluctuations or surges. Ensure that the pressure rating of the fitting can accommodate these variations.

Temperature:Check the temperature range of your application. Some materials, including HDPE, can experience changes in mechanical properties at extreme temperatures. Ensure that the fitting's pressure rating is valid for the temperature range.

Fluid Type:Evaluate the type of fluid that will flow through the piping system. Certain fluids, such as chemicals or aggressive substances, might require specific pressure ratings to prevent deterioration of the fitting.

Application Type:Determine the nature of your application. Is it a water supply system, a drainage system, or an industrial process? Different applications might have different pressure requirements.

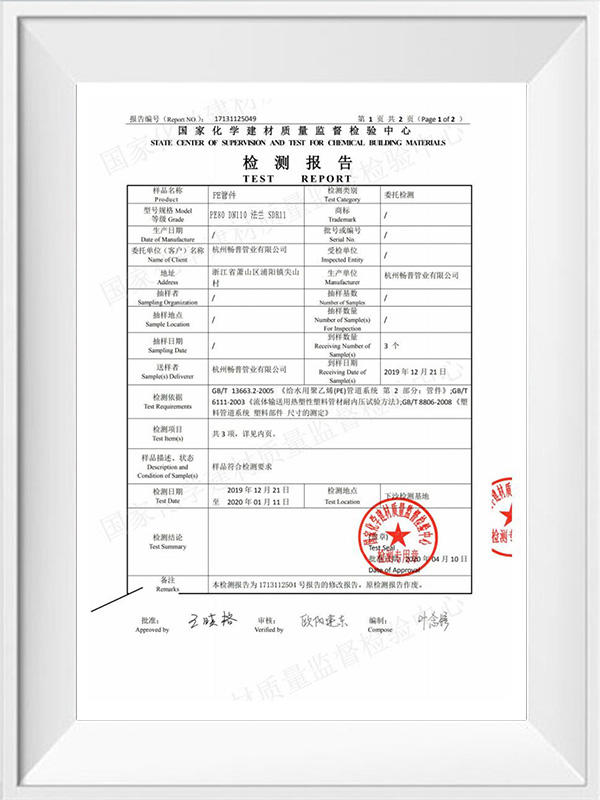

Industry Standards and Regulations:Check if there are industry standards, codes, or regulations that dictate the pressure rating for fittings in your specific application. Make sure the fitting meets or exceeds these requirements.

Safety Margin:It's a good practice to have a safety margin when considering pressure ratings. Select a fitting with a pressure rating higher than the maximum operating pressure to account for unforeseen circumstances.

Consult Data:Refer to the manufacturer's documentation, product datasheets, or technical specifications for detailed information about the fitting's pressure rating and its compatibility with various applications.

Consultation:If you're uncertain about whether the pressure rating is suitable for your application, consult with experts who specialize in HDPE piping systems. They can provide guidance based on their experience.

It's crucial to ensure that the pressure rating of the HDPE equal tee butt fusion fitting aligns with the specific requirements of your application. Fittings with an appropriate pressure rating will contribute to the safe and reliable operation of your piping system over its lifespan.

English

English Español

Español русский

русский عربى

عربى

.jpg?imageView2/2/format/jp2)