| Name | Male tee PP compression fitting |

| Size | 20 × 1/2".-110 × 4" |

| Pressure | SDR11(PN16),SDR17(PN10) |

| Package | Carton |

| Color | BLACK body+bule cap |

| Technics | Mould injection |

| Loading port | Ningbo or Shanghai port |

| Place of origin | Hangzhou |

-

AddressZheJiang, China

-

Phone+86-17367068772

-

E-mail[email protected]

Male tee PP compression fitting

Male tee PP compression fitting produced by injection mould and both side with different size. And it consists of five parts (locking nut, Clinching ring, Blocking bush, O Ring gasket and body)

Get A Quote

Reference Standards

✱Working Pressures

UNI 9561-2, DIN 8076, ISO 14236, BRL-K03

✱ Threads: ISO 7,ANSIASME B1-20

✱Flanges:ISO2084,DIN2501,UN17442

About Us

Hangzhou Changpu Pipe Industry Co., Ltd.

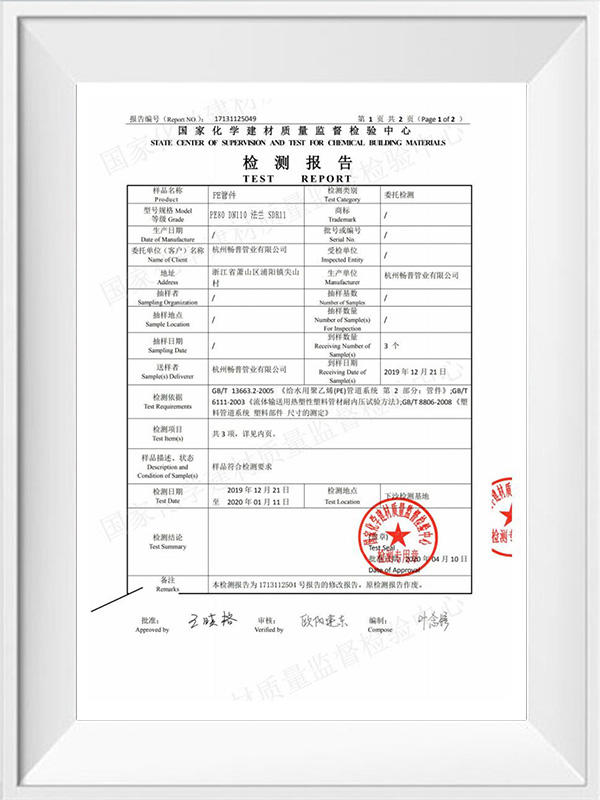

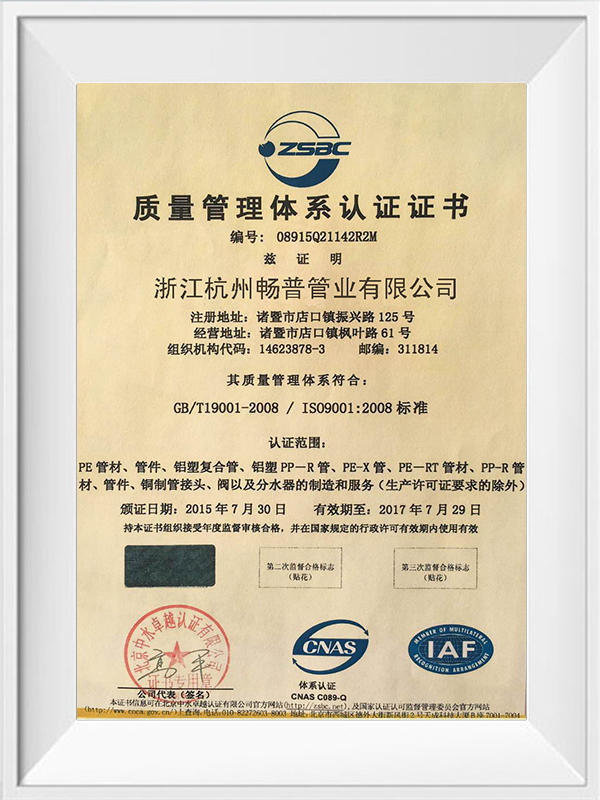

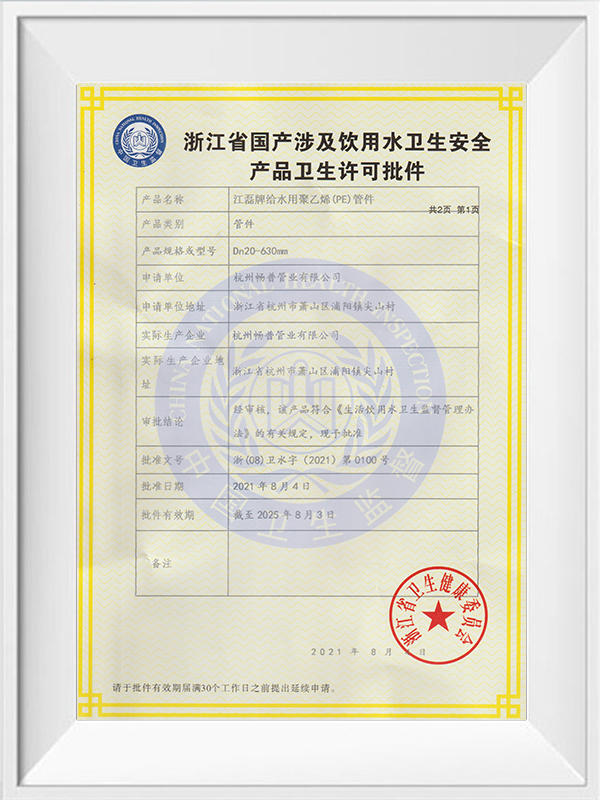

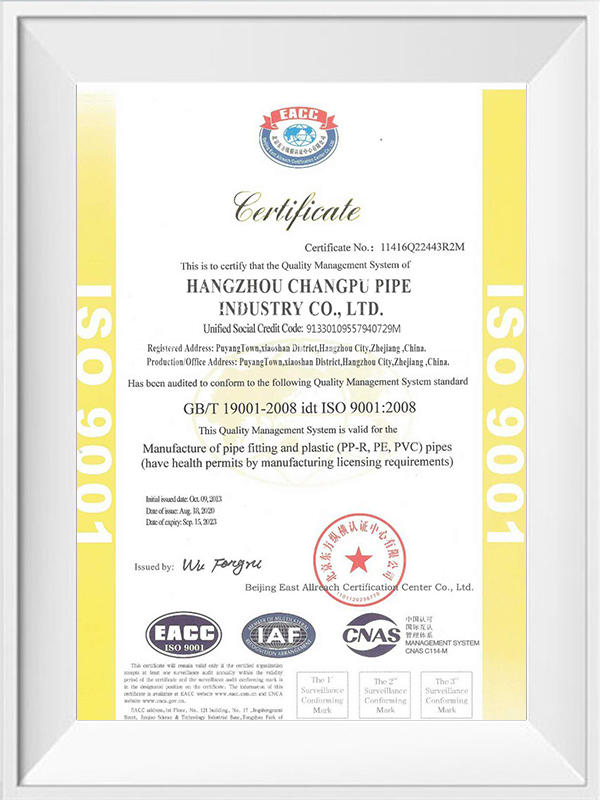

Hangzhou Changpu Pipe Industry Co., Ltd. was established in 2010, which is a professional factory major in the production of polyethylene (PE) Butt fusion fittings, Socket fusion fittings, Electrofusion fittings, PE stop valves, PE /Steel transition fittings, repair clamp ETC. Male tee PP compression fitting manufacturers and factory in China. Our products pass the test from National Chemical Building Materials Testing Center,all performance indicators are in compliance with the GB 15558.2 / EN1555 standards. Also they certified by ECM and obtain CE certification.

We focus on developing high-quality products for top-end markets. Our oem custom Male tee PP compression fitting are in line with international standards, and are mainly exported to Europe, America, Japan and other destinations around the world.We welcome domestic and foreign customers visit our company for guidance, exchanges and cooperation.

News

-

How does Hdpe Thread Fitting balance sealing and installation convenience in pipe connection?

HDPE Thread Fitting is widely used in water supply, drainage......--15 May 2025

READ MORE -

Socket Fusion HDPE Fitting is a pipe solution for efficient connection

In modern construction projects, municipal water supply and ......--09 May 2025

READ MORE -

Is Hdpe Valve suitable for high temperature or corrosive media?

HDPE valves have been widely used in municipal water supply ......--04 May 2025

READ MORE -

How to ensure the long-term reliability and durability of Butt Fusion HDPE Fittings in high pressure and high temperature environments?

Ensuring the long-term reliability and durability of Butt Fu......--23 Apr 2025

READ MORE -

Do Butt Fusion HDPE Fittings require additional protection to extend their service life?

Butt Fusion HDPE Fittings generally have a long service life......--14 Apr 2025

READ MORE

Product Knowledge

The expected lifespan of a male tee PP compression fitting can vary based on several factors, including the quality of the fitting, the material used, installation practices, the operating environment, and maintenance. PP compression fittings are generally designed to be durable and long-lasting, but the actual lifespan can range from several years to decades. Here are some factors that can influence the lifespan of a male tee PP compression fitting:

Material Quality: High-quality PP materials and fittings made from virgin (new) materials tend to have better longevity and resistance to wear and degradation.

Operating Conditions: The temperature, pressure, and chemical exposure of the operating environment can impact the lifespan of the fitting. Extreme conditions, such as high temperatures or corrosive chemicals, can potentially reduce the lifespan.

Installation Quality: Proper installation practices are crucial. Incorrect installation, overtightening, or inadequate sealing can lead to premature failure of the fitting.

Maintenance: Regular maintenance and inspections can identify any signs of wear, damage, or deterioration early on, allowing for timely replacements.

UV Exposure: If the fitting is exposed to direct sunlight or outdoor conditions, UV-resistant fittings tend to have longer lifespans.

Water Quality: The quality of the water flowing through the fitting can also influence its lifespan. Corrosive water or water with high mineral content can impact the fitting's performance over time.

Frequency of Use: The frequency at which the fitting is subjected to pressure changes and temperature variations can affect its wear and tear.

Physical Impact: Physical impacts or accidental damage can cause fittings to fail prematurely.

Compatibility: Ensure that the fitting is compatible with the type of pipes and materials it is connected to.

Code Compliance: Choosing fittings that comply with relevant plumbing codes and standards can contribute to their longevity.

It's important to note that while a male tee PP compression fitting might have a long lifespan, routine inspections and periodic replacements are recommended to maintain the integrity of your plumbing system. If you notice signs of leakage, wear, or degradation, it's best to address the issue promptly to prevent potential damage or system failure.

English

English Español

Español русский

русский عربى

عربى

.jpg?imageView2/2/format/jp2)