The cost of

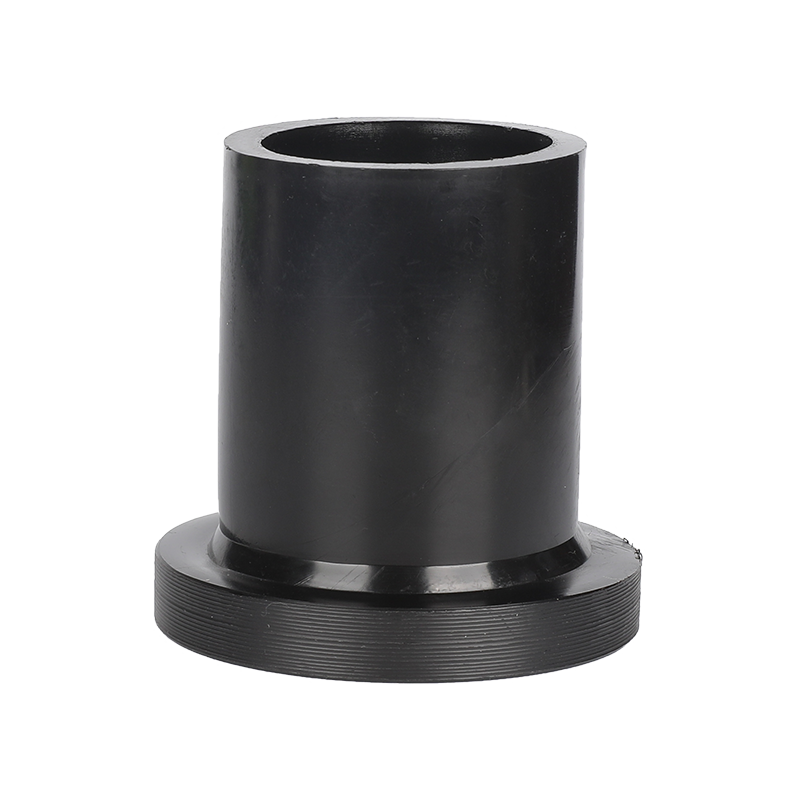

HDPE electrofusion equal tees can vary depending on several factors, including the size, material quality, manufacturer, region, and specific supplier. It's important to consider the initial cost as well as the long-term value and performance when comparing HDPE electrofusion equal tees to alternative materials or fitting types.

Here are some factors to consider when comparing costs:

1. Initial Cost:HDPE electrofusion equal tees might have an initial cost that includes the price of the fitting itself, as well as any associated installation equipment or tools required for the electrofusion process.

2. Installation Costs:The installation process for HDPE electrofusion fittings typically requires specialized equipment for electrofusion welding. This can impact the overall installation cost compared to other types of fittings that might use different joining methods.

3. Long-Term Value:HDPE is known for its durability and resistance to corrosion, chemicals, and UV exposure. This can result in reduced maintenance and replacement costs over the life of the system.

4. Material Properties:Consider the specific properties of HDPE, such as its lightweight nature, flexibility, and ease of installation. These properties can impact labor costs and overall project timelines.

5. Comparison to Alternative Materials:Compare the cost of HDPE electrofusion equal tees to alternative materials such as traditional metal fittings, PVC (Polyvinyl Chloride) fittings, or other plastic materials. Take into account the material's longevity, maintenance needs, and potential for leaks or failures over time.

6. Project Requirements:The complexity of the project, the number of fittings required, and the size of the piping system can all influence the overall cost. Larger projects might benefit from the cost advantages of HDPE, especially if the labor and installation time can be reduced.

7. Local Availability:The availability of HDPE fittings and materials in your region can affect the cost. If HDPE is readily available locally, it might have competitive pricing compared to other materials.

When comparing costs, it's essential to look beyond the initial price tag and consider factors such as installation efficiency, maintenance requirements, lifespan, and the overall performance of the chosen material or fitting type. HDPE's advantages in terms of durability, chemical resistance, and ease of installation often contribute to its long-term value and cost-effectiveness.

English

English Español

Español русский

русский عربى

عربى

.jpg?imageView2/2/format/jp2)