To ensure that the

HDPE female adapter is compatible with the diameter and specifications of the HDPE pipe you are connecting, you need to consider several factors to ensure a proper fit and a reliable connection:

Pipe Diameter: The most critical factor is matching the diameter of the HDPE pipe with the female adapter's size. The female adapter should be designed to connect with the specific diameter of the HDPE pipe.

Pipe Material: Confirm that both the HDPE pipe and the female adapter are made from compatible HDPE materials. Using materials of different types or qualities can lead to issues during the fusion process and the overall performance of the joint.

Pressure Rating: Ensure that the pressure rating of the HDPE female adapter aligns with the pressure requirements of the piping system. The adapter should be capable of withstanding the intended operating conditions.

Thread Compatibility: If the female adapter includes threads, make sure that the threads match the type of connection you need. Common thread standards include NPT (National Pipe Thread) or others. The threads should be compatible with the male fitting you're connecting.

Fusion Techniques: Understand the fusion techniques used for connecting the female adapter to the HDPE pipe. Depending on the design, you might need to use butt fusion, socket fusion, or another appropriate fusion method.

Installation Procedures: This includes steps for preparing the pipe ends, heating the surfaces for fusion, and achieving a secure and leak-free joint.

Gasket or Sealing Mechanism: If the female adapter includes a gasket or sealing mechanism, ensure that it's designed to work with the specific type of fluid or material that will flow through the pipes.

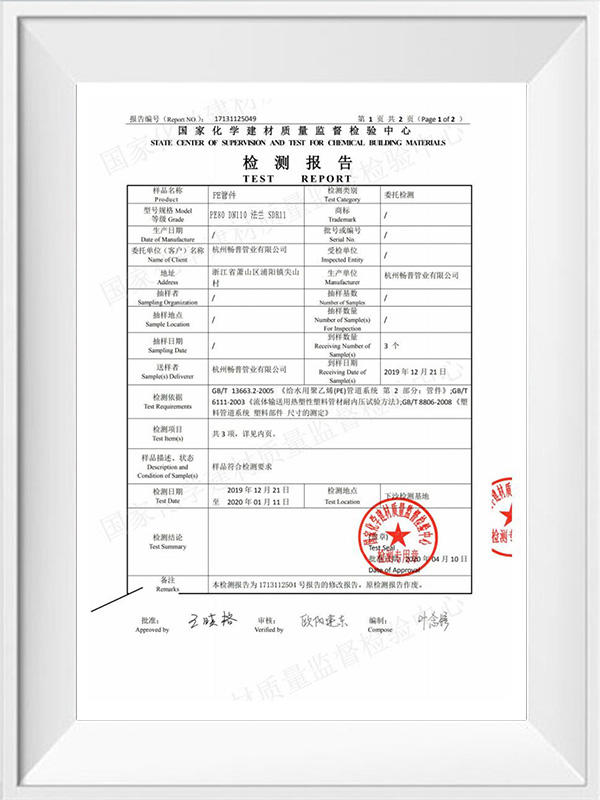

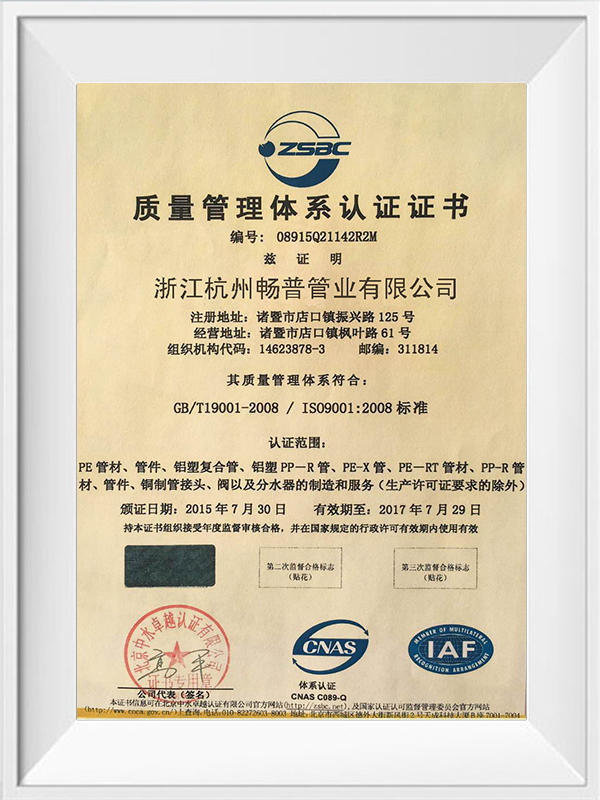

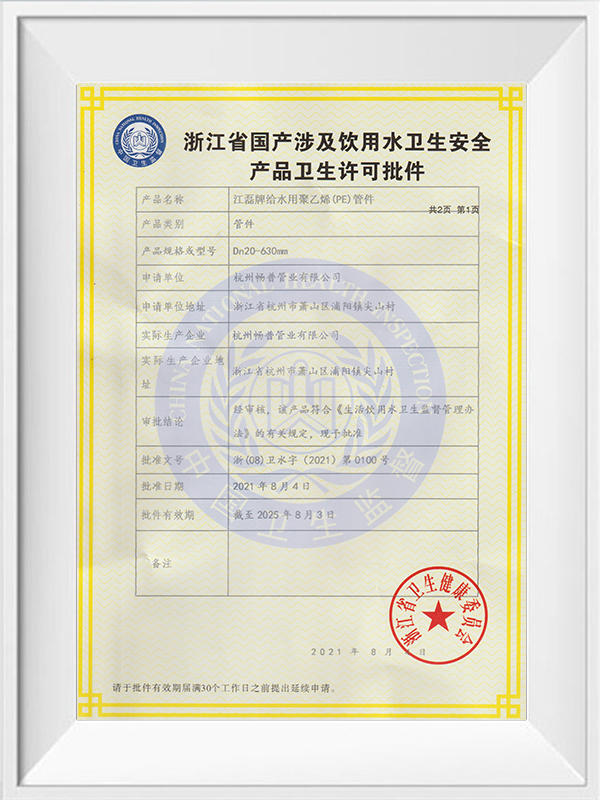

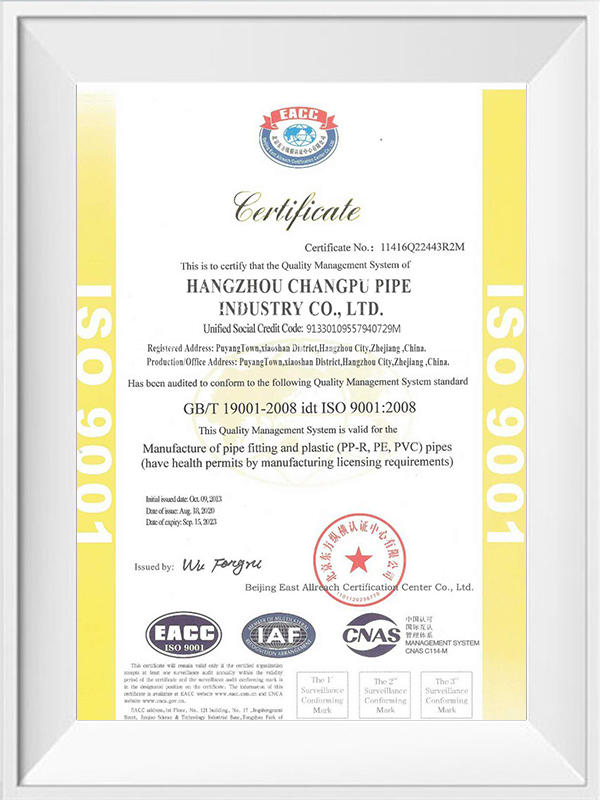

Standards and Certifications: Check if the HDPE female adapter complies with industry standards and certifications. This can ensure that it has been tested and approved for use in specific applications.

Proper compatibility is crucial for creating a strong, leak-free, and durable connection between the HDPE pipe and the female adapter. Mistakes in selecting incompatible components can lead to leaks, system inefficiencies, and failures, so it's important to ensure a precise match.

English

English Español

Español русский

русский عربى

عربى

.jpg?imageView2/2/format/jp2)