The cost of

HDPE socket fusion tee reducers can vary depending on factors such as the size, quality, and the specific market or region you're sourcing them from. When comparing the cost of HDPE socket fusion tee reducers to alternative materials or fitting types, consider the following factors:

Material Costs:HDPE socket fusion tee reducers are made from HDPE material, which may have different pricing compared to other materials like metal or PVC. The cost of raw materials can influence the overall cost of the fitting.

Manufacturing Process:The manufacturing process of HDPE fittings can impact their cost. Injection molding and fusion techniques are commonly used for HDPE fittings, and these processes can affect production costs.

Installation Costs:HDPE socket fusion fittings often require specialized tools and equipment for proper installation. Consider the cost of training personnel to use these tools and the time required for installation.

Labor Costs:The labor involved in installing HDPE socket fusion fittings might differ from that of alternative materials. Factors such as fusion time and skill level needed can influence labor costs.

Fitting Type and Size:The cost of different types and sizes of HDPE fittings can vary. Larger and more complex fittings, such as reducers, might have higher costs compared to simpler fittings.

Alternative Materials:Compare the cost of HDPE socket fusion tee reducers to alternatives like metal (such as stainless steel or copper) or other plastic materials (such as PVC or CPVC). Consider the material costs, manufacturing processes, and installation requirements of these alternatives.

Long-Term Costs:While the upfront cost of HDPE fittings might vary, consider the long-term cost savings associated with HDPE's durability, resistance to corrosion and chemicals, and potentially lower maintenance needs.

Project Scope:The scale of your project can influence pricing. Bulk purchases might lead to volume discounts, while smaller projects might have different cost structures.

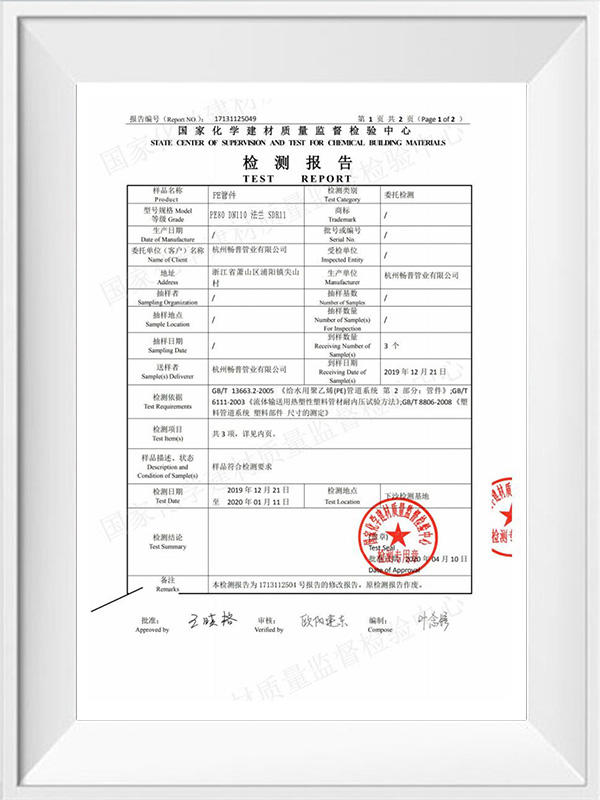

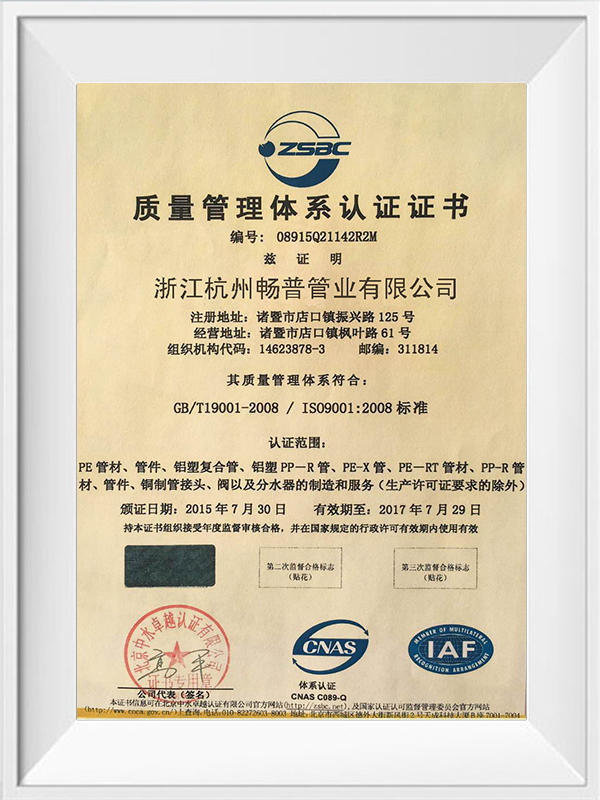

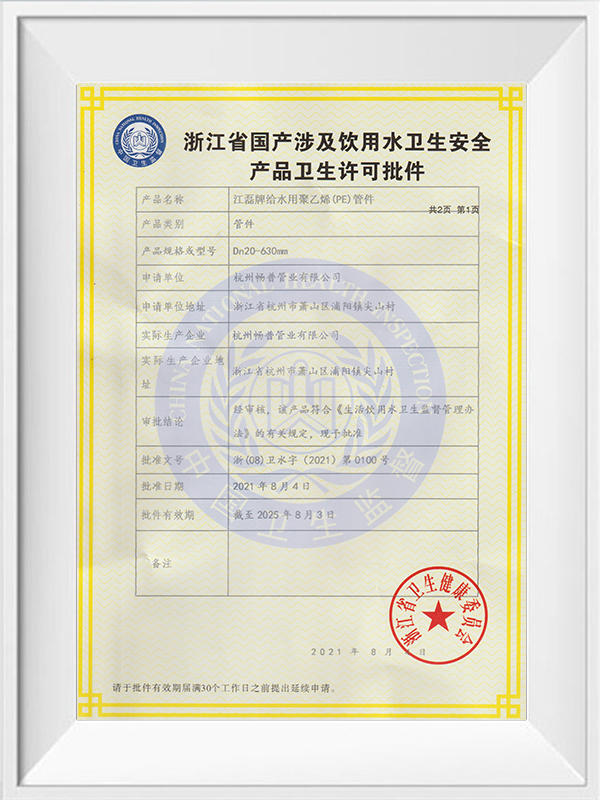

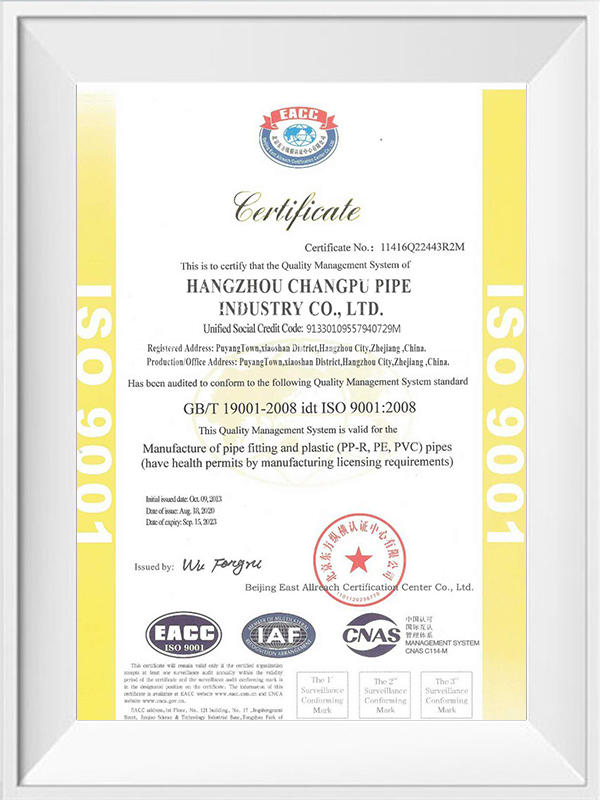

Certifications and Standards:HDPE fittings that meet specific industry standards or certifications might have higher associated costs due to the quality assurance processes involved.

When comparing costs, it's important to consider the overall value of the fitting in terms of its suitability for the application, longevity, and maintenance requirements. While HDPE socket fusion fittings might have an initial cost, their long-term benefits can often justify the investment due to their durability and resistance to various environmental factors.

English

English Español

Español русский

русский عربى

عربى

.jpg?imageView2/2/format/jp2)