| SIZE | VOLTAGE/FREQUENCY | TOTAL POWER | HEATING PLATE POWER | PLANNING TOOL POWER | HYDRAULIC UNIT POWER | WEIGHT | VOLUME |

| 63-160MM | 220v,50/60HZ | 2.45KW | 0.9KW | 0.8KW | 0.75KW | 100KG | 0.4CBM |

| 63-200MM | 220v,50/60HZ | 2.75KW | 1.2KW | 0.8KW | 0.75KW | 105KG | 0.4CBM |

| 90-250MM | 220v,50/60HZ | 4.75KW | 2.2KW | 1.8KW | 0.75KW | 147KG | 0.5CBM |

| 90-315MM | 220v,50/60HZ | 5.35KW | 2.8KW | 1.8KW | 0.75KW | 180KG | 1.0CBM |

| 200-400mm | 220v,50/60HZ | 7.2KW | 5.0KW | 1.1KW | 1.1KW | 350KG | 1.8CBM |

| 400-630mm | 220v,50/60HZ | 10.6KW | 8.0KW | 1.5KW | 1.1KW | 610KG | 2.8CBM |

-

AddressZheJiang, China

-

Phone+86-17367068772

-

E-mail[email protected]

Hydraulic butt welding machine

Hydraulic butt welding machine brief&features

Get A Quote

❆Suitable for butt welding of plastic pipes and fittings made of PE, PP, PPR and PVDF in worksite or workshop.

❆Consists of basic frame, hydraulic unit, planning tool, heating plate, support for planning tool & heating plate and other optional parts.

❆Removable PTFE coated heating plate with separate temperature control system.

❆Electric planning tool.

❆Be made of light weight and high strength material; simple structure, small and exquisite, easily use.

❆Low starting pressure ensures reliable welding quality of small pipes.

❆Changeable welding position enables to weld various fittings more easily.

❆Large dial, high-precision shock-proof pressure gauge, clearer reading

❆Configure fast, labor-saving heating plate, milling cutter lift.

About Us

Hangzhou Changpu Pipe Industry Co., Ltd.

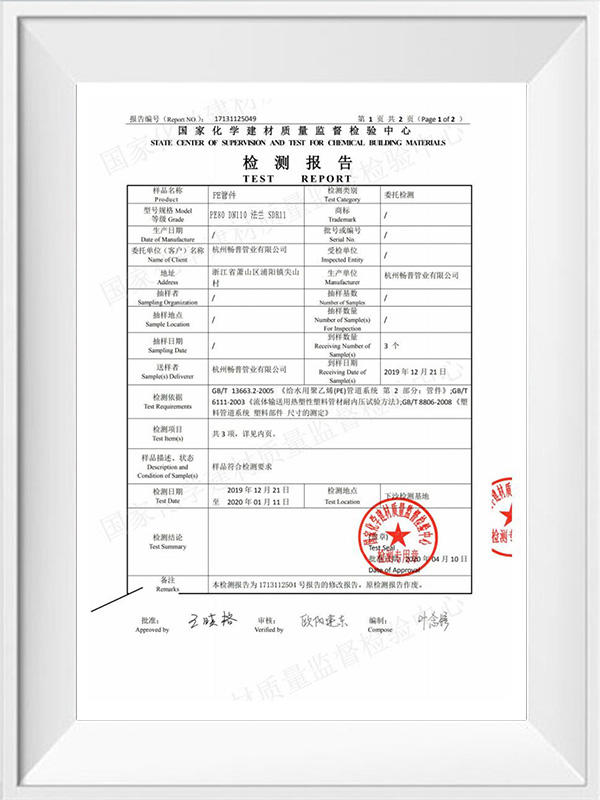

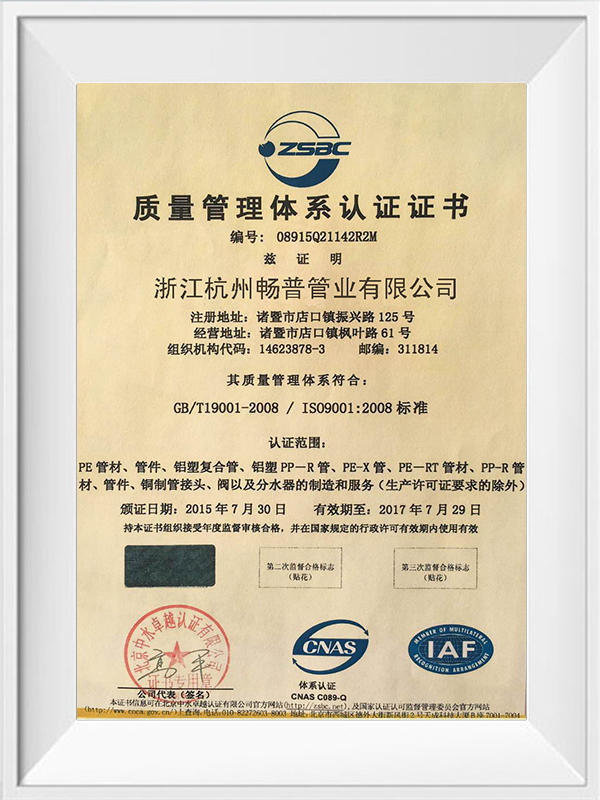

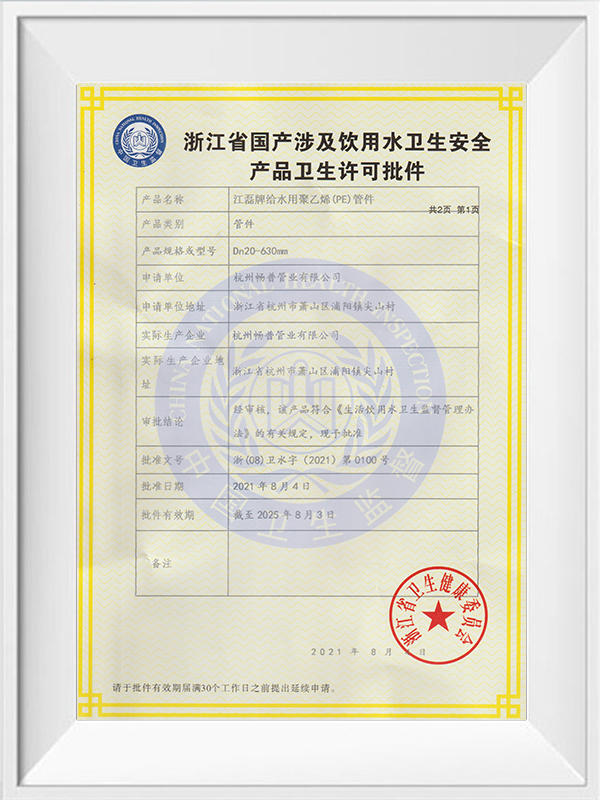

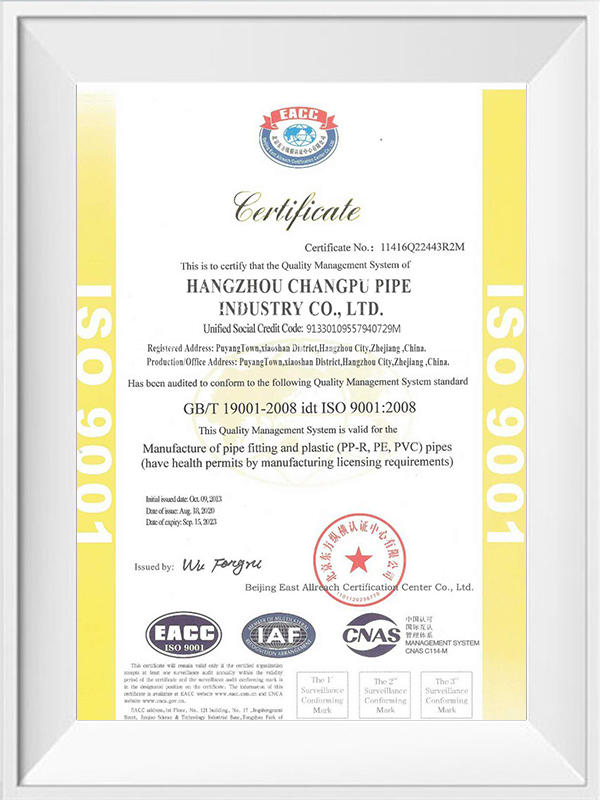

Hangzhou Changpu Pipe Industry Co., Ltd. was established in 2010, which is a professional factory major in the production of polyethylene (PE) Butt fusion fittings, Socket fusion fittings, Electrofusion fittings, PE stop valves, PE /Steel transition fittings, repair clamp ETC. Hydraulic butt welding machine manufacturers and factory in China. Our products pass the test from National Chemical Building Materials Testing Center,all performance indicators are in compliance with the GB 15558.2 / EN1555 standards. Also they certified by ECM and obtain CE certification.

We focus on developing high-quality products for top-end markets. Our oem custom Hydraulic butt welding machine are in line with international standards, and are mainly exported to Europe, America, Japan and other destinations around the world.We welcome domestic and foreign customers visit our company for guidance, exchanges and cooperation.

News

-

How does Hdpe Thread Fitting balance sealing and installation convenience in pipe connection?

HDPE Thread Fitting is widely used in water supply, drainage......--15 May 2025

READ MORE -

Socket Fusion HDPE Fitting is a pipe solution for efficient connection

In modern construction projects, municipal water supply and ......--09 May 2025

READ MORE -

Is Hdpe Valve suitable for high temperature or corrosive media?

HDPE valves have been widely used in municipal water supply ......--04 May 2025

READ MORE -

How to ensure the long-term reliability and durability of Butt Fusion HDPE Fittings in high pressure and high temperature environments?

Ensuring the long-term reliability and durability of Butt Fu......--23 Apr 2025

READ MORE -

Do Butt Fusion HDPE Fittings require additional protection to extend their service life?

Butt Fusion HDPE Fittings generally have a long service life......--14 Apr 2025

READ MORE

Product Knowledge

A hydraulic butt welding machine, also known as a hydraulic fusion welding machine, is a specialized tool used for joining plastic pipes and fittings through the butt fusion welding process. Butt fusion is a common method for connecting thermoplastic pipes, such as High-Density Polyethylene (HDPE) pipes, in applications like water distribution, gas pipelines, industrial processes, and more.

Here's what you need to know about hydraulic butt welding machines:

Function: A hydraulic butt welding machine is designed to create strong and leak-free joints between plastic pipes and fittings. It works by heating the ends of the pipes and fittings, then pressing them together under hydraulic force to create a fused joint.

Principle: The butt fusion welding process involves placing the pipe ends facing each other within the machine's clamps. The machine then heats the pipe ends using heating elements, and once they reach the appropriate melting point, the clamps bring the pipe ends together under controlled hydraulic pressure.

Components: A hydraulic butt welding machine typically includes clamps to hold the pipes, a hydraulic unit for applying pressure, a heating element to heat the pipe ends, and a control panel for setting parameters.

Hydraulic Pressure: The hydraulic unit provides the necessary pressure to ensure proper fusion of the pipe ends. Controlled pressure is crucial for achieving consistent and strong joints.

Heating Element: The machine is equipped with heating elements that bring the pipe ends to the required fusion temperature. The heating process ensures that the pipe material becomes molten and fuses together effectively.

Cooling Time: After fusion, the joint requires a cooling cycle during which the melted material solidifies and forms a strong bond.

Sizes and Compatibility: Hydraulic butt welding machines come in various sizes to accommodate different pipe diameters and wall thicknesses. Choose a machine that matches the sizes you'll be working with.

Safety: Operators must adhere to safety protocols when using hydraulic butt welding machines, including electrical safety, pressure control, and proper handling of heated components.

Quality Joints: Butt fusion welding produces high-quality, seamless, and leak-free joints that retain the strength and integrity of the original pipe material.

Applications: Hydraulic butt welding machines are used in a wide range of industries for connecting plastic pipes, including water and gas distribution, industrial processes, sewage systems, and more.

Training: Proper training is essential for using hydraulic butt welding machines. Operators should understand the machine's operation, safety practices, and the specific requirements of the materials being fused.

Hydraulic butt welding machines are crucial tools for creating reliable and robust joints in plastic piping systems. When operated correctly, these machines ensure efficient and durable connections that meet the performance standards of the application.

English

English Español

Español русский

русский عربى

عربى

.jpg?imageView2/2/format/jp2)